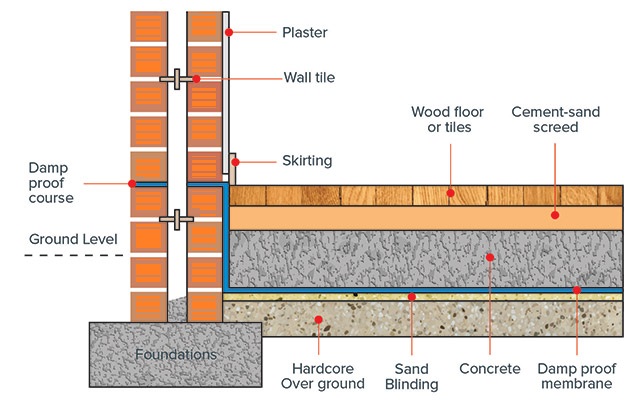

In order to prevent the entry of damp or moisture in the building the damp-proofing courses (D.P.C) are provided at various levels of entry of damp in to a building. At present practically all the buildings are given the treatment of damp-proofing. Thus the provision of D.P.c prevent the entry of moisture from walls, floors, and basement of a building. Following are the various causes of dampness in a building:

- Rising of moisture from the ground

- Rain travel from wall tops

- Rain beating against external walls

- Condensation

- Poor drainage, imperfect orientation, imperfect roof slope, defective construction etc.

The ideal damp proofing material have the following characteristics:

- It should be perfectly impervious

- It should be durable

- It should be strong and capable of resisting superimposed load coming on it.

- It should be flexible so that it can accommodate the structural movements without any fracture.

- It should remain steady in its position when once applied

- It should not be costly.

The materials commonly used for damp-proofing are not bitumen, mastic asphalt, bituminous or asphaltic felts, metal sheets, combination of sheets are felts, stone, bricks, mortar, cement concrete and plastic sheets.

The following general principles should be kept in mind while providing D.P.C.

- The damp-proofing course may be horizontal or vertical.

- The horizontal damp-proof course ahould cover the full thickness of wall, excluding rendering.

- The damp-proof course should be so laid that a continous projection is provided.

- At junctions and cornersof walls, the horizontal damp-proof course should be laid continous.

- The mortar bed supporting the damp-proof course should be even and levelled and should be free from projections so that the damp proof course is not damaged.

- The damp proof course should not be kept exposed on the wall surface otherwise it may get damaged during finishing work.

- When a horizontal damp proof course is continued to a vertical face a cement concrete fillet of about 75 mm radius should be provided at he junction.